Concrete construction has evolved rapidly over the years, and one technique that has completely changed how concrete is placed on job sites is concrete pumping. Whether it is a residential driveway, a multi-storey commercial building, or a hard-to-reach foundation area, concrete pumping makes the job faster, cleaner, and far more efficient.

This beginner’s guide explains everything you need to know about concrete pumping, how it works, why it is used, the different types of pumps, and when it is the right choice for your project. If you are new to the construction world or simply want to understand modern concrete placement methods, this guide is for you.

Understanding the Basics of Concrete Pumping

Concrete pumping is the process of transporting liquid concrete from a mixer truck directly to the desired location using a specialized machine called a concrete pump. Instead of relying on wheelbarrows, buckets, or cranes, the pump pushes concrete through pipes or hoses with precision and control.

In traditional concrete placement, labour costs are high, work is slow, and access can be a significant issue. Concrete pumping solves these challenges by allowing concrete to be placed precisely where it’s needed, even in tight spaces or elevated areas.

Why Concrete Pumping Is Used in Modern Construction

In today’s fast-paced construction environment, efficiency and accuracy matter more than ever. Concrete Pumping has become a preferred method because it significantly reduces manual labour, minimizes waste, and speeds up project timelines.

By the second or third stage of most modern projects, contractors realize the value of pumping concrete rather than manually placing it. It ensures consistent flow, better compaction, and a smoother finish, especially for slabs, footings, and structural elements.

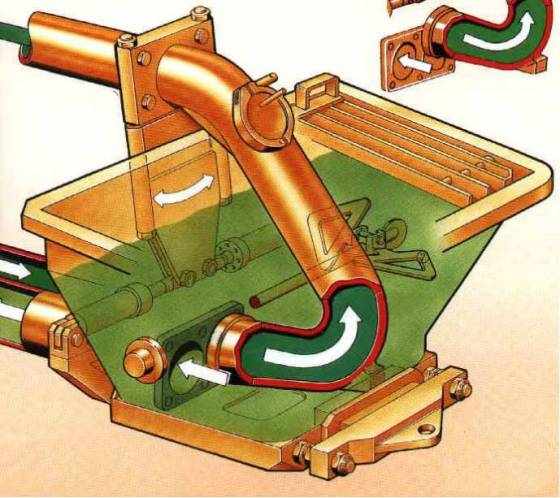

How a Concrete Pump Works

A concrete pump works by using hydraulic pressure to push concrete through a delivery system. The process starts when ready-mix concrete is poured into a hopper attached to the pump. From there, powerful pistons move the concrete through steel pipes or flexible hoses until it reaches the pour point.

The operator controls the speed and pressure, ensuring the concrete flows smoothly without segregation. This controlled delivery is one of the most significant advantages of using a concrete pump, particularly for complex or large-scale projects.

Types of Concrete Pumps Explained

Not all projects require the same type of equipment. There are different types of concrete pumps, each designed for specific construction needs.

Boom Concrete Pump

A boom pump is mounted on a truck and features a robotic arm that can extend and rotate. This type is ideal for high-rise buildings, bridges, and large commercial projects where concrete needs to be delivered over long distances or heights.

Concrete Line Pump

A concrete line pump uses flexible hoses or steel pipelines laid along the ground or through structures. It is perfect for residential projects, backyards, driveways, footpaths, and areas with limited access. Line pumps are cost-effective and highly versatile, making them a popular choice for smaller to medium-sized jobs.

Benefits of Using Concrete Pumping

Concrete pumping offers a wide range of benefits that make it superior to traditional placement methods.

Faster Project Completion

Concrete can be placed quickly and continuously, reducing downtime and speeding up construction schedules.

Reduced Labor Costs

Fewer workers are needed to move and place concrete manually, lowering overall labour expenses.

Improved Accuracy and Quality

Concrete is delivered precisely where required, leading to better structural integrity and a cleaner finish.

Access to Difficult Areas

Concrete pumping makes it possible to pour concrete in areas that are otherwise unreachable, such as narrow sites, elevated floors, or enclosed spaces.

Where Concrete Pumping Is Commonly Used

Concrete pumping is suitable for a wide range of construction applications, including:

Residential house slabs and footings

Driveways and pathways

Commercial floors and foundations

Retaining walls and columns

Industrial and civil construction projects

Because of its flexibility, concrete pumping is used in both small residential jobs and large-scale commercial developments.

Concrete Pumping vs Traditional Concrete Placement

Traditional concrete placement methods rely heavily on manual labour and basic equipment. While this may work for tiny projects, it becomes inefficient and costly for anything larger.

Concrete pumping, on the other hand, offers consistent flow, reduced spillage, and faster placement. It also improves workplace safety by minimizing physical strain on workers and reducing site congestion.

Factors That Affect Concrete Pumping Costs

The cost of concrete pumping can vary depending on several factors:

Type of concrete pump required

Distance and height of the pour

Volume of concrete

Site accessibility and setup time

Although concrete pumping may seem more expensive upfront, it often saves money in the long run by reducing labour, delays, and material waste.

Tips for a Successful Concrete Pumping Job

To get the best results from concrete pumping, proper planning is essential.

Ensure site access is clear for pump setup

Use the correct concrete mix for pumping

Communicate clearly with the pump operator

Schedule the pour to avoid delays

A well-planned concrete pumping job leads to smoother operations and higher-quality results.

The Role of Professional Concrete Pumping Services

Using experienced professionals ensures that the concrete pumping process is carried out safely and efficiently. Skilled operators understand pressure control, flow rates, and site conditions, which helps prevent blockages and ensures consistent placement.

Professional services also maintain their equipment to high standards, reducing the risk of breakdowns during critical pours.

Conclusion: Is Concrete Pumping Right for You?

Concrete pumping has become an essential part of modern construction due to its speed, accuracy, and versatility. Whether you are working on a residential slab or a large commercial project, using a concrete pump or concrete line pump can save time, reduce costs, and improve overall quality.

For beginners, understanding the basics of concrete pumping helps in making informed decisions and planning projects more effectively. As construction demands continue to grow, concrete pumping remains one of the most innovative solutions for efficient concrete placement.

Write a comment ...